What Are the Steps to Get Prototype PCB Manufactured Circuit Diagram Creating a PCB prototype is an important step in the product development process as it allows you to test and verify your design on a limited scale before committing to full production. With careful planning, attention to detail, and patience during assembly, prototyping can be used to identify any potential issues or adjustments that need to Introduction. A printed circuit board (PCB) prototype is an early sample version of a PCB designed to test the viability of the PCB design before full-scale manufacturing. Building a high-quality PCB prototype is a crucial step in the electronics design process, allowing the designer to verify the PCB's functionality and catch any errors before committing to mass production. PCB Prototyping Steps: A Simple Guide to Getting Started. Creating a PCB prototype involves several key steps. Here's a quick breakdown of the PCB prototyping process:. Design the Schematic: This is your circuit blueprint, outlining all components and their connections.. Create the PCB Layout: Place components and route traces, ensuring proper electrical flow.

However, if the prototype PCB does not meet all of the required specifications or is unacceptable, the problem is probed by conducting a detailed design review. After the design review, a new iteration starts by making the necessary design amendments at the appropriate level, i.e., circuit design, PCB layout, PCB material selection, etc.

How to Make a PCB Prototype? Circuit Diagram

Costs of Prototype PCB Production. Prototyping printed circuit boards in low quantities generally costs between $200 - $5000 depending on size, layer count, and manufacturing method used. Typical PCB Prototype Cost Drivers: Number of layers - more layers increases cost. Board dimensions - larger boards cost more. Having access to a variety of PCB materials is essential for tailoring your prototypes to specific requirements. Research and identify suppliers or distributors of PCB materials compatible with your projects. Utilizing these tools and resources can streamline the rapid PCB prototyping process and make it more efficient. PCB prototype advantages and disadvantages. PCB prototype advantages. 1. Reduces time and effort Using prototyping helps quickly assemble the components and test out the design idea to verify its suitability. For example, solderless breadboards allow connecting all the components using jumper cables, therefore, reducing time and effort.

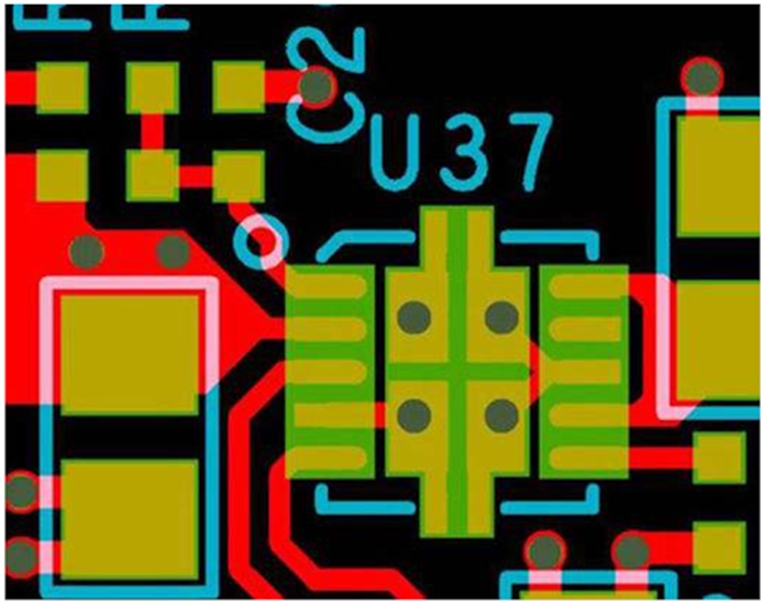

A PCB prototype is a preliminary version of the final PCB design, used for testing, evaluation, and refinement before moving into full-scale production. Prototyping is an essential step in the development cycle, allowing engineers and designers to validate their designs, identify potential issues, and make necessary modifications before Steps to Make a PCB Prototype. Follow these steps to create your very own PCB prototype: Design Your Circuit. The first step in creating a PCB prototype is to design your circuit. This can be done using PCB design software such as Eagle, KiCad, or Altium Designer. These tools allow you to create a schematic diagram of your circuit, place Creating PCB prototypes requires carefully executing multiple steps - schematic capture, board layout, design rules checks, generating Gerber files, material selection, assembly, quality testing. Using the right design software and prototype assembly services helps streamline the process. Investing time upfront in design reviews helps avoid